Centralized Coolant Filtration & Recycling Systems

Filter-Chill or Recycle Coolant or Machining Oils From Multiple Machines Using One Centralized System!

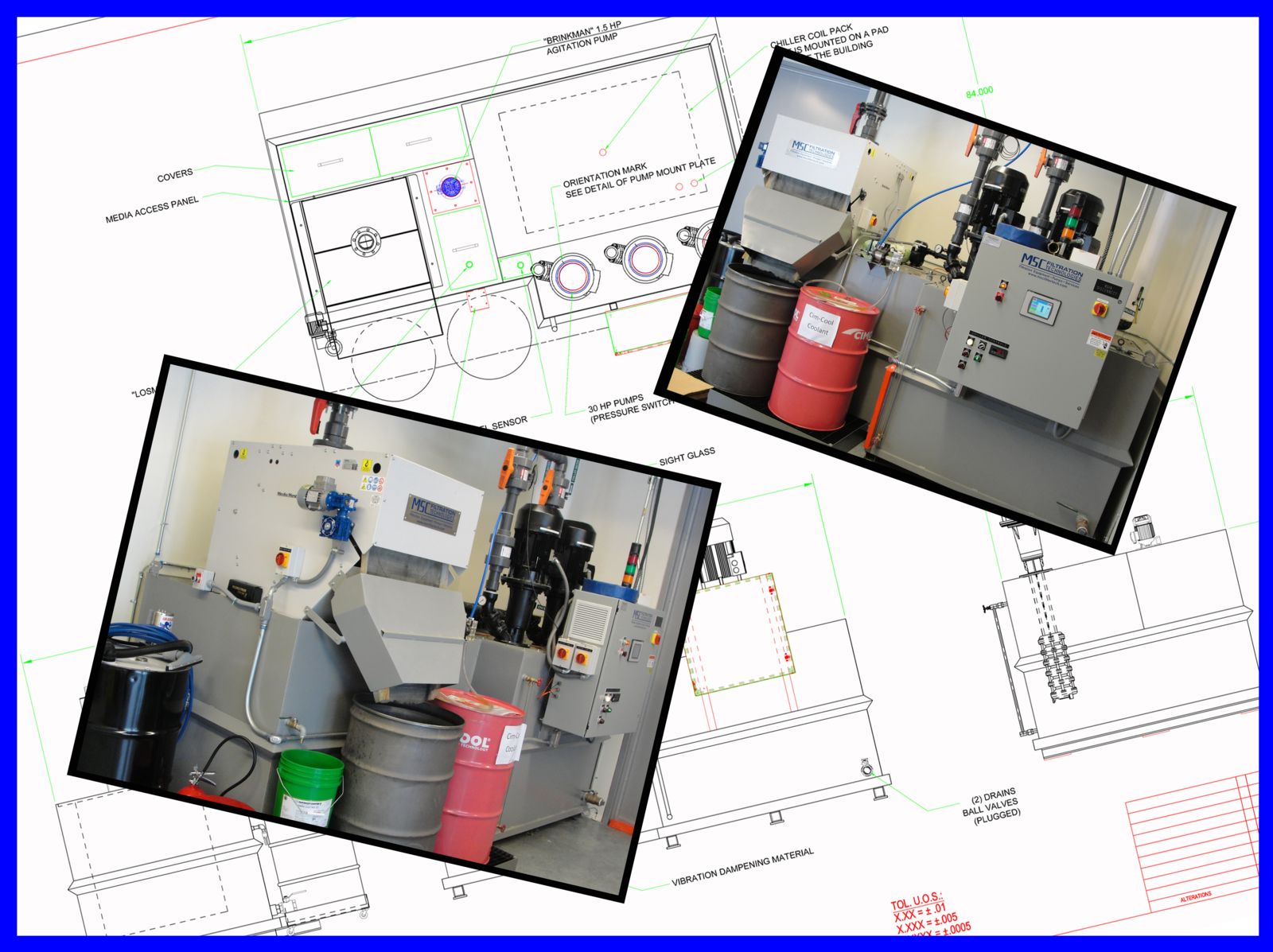

Since 1962 MSC Filtration Technologies has been designing and engineering custom built centralized multi machine coolant filtration and recycling systems in Enfield, CT USA. Over this time MSC has gained the knowledge, engineering talent and expertise to integrate a wide variety of coolant handling technologies into its systems including Coolant Pumps, Chip Conveyors, Chillers, Heat Exchangers Tramp Oil Separators, Indexing Filters and Magnetic Filters among other technologies to keep your machines running with their coolant within manufacturer's operating cleanliness and temperature specifications.

MSC is a manufacturer of custom centralized coolant handling systems.

Product Info

Why Custom Systems

MSC has been building customized coolant recycling systems for over 50 years. Because of this MSC is able to utilize its engineering experiences and past designs to build the most effective and affordable systems for our customers needs regardless of what level of automation is required. Please see an example below of where MSC helped save our customer over $20,000 per month in lost revenue which then paid the system off in less than 4 months.

MSC's custom built systems are designed to be as manual or autonomous as our customers require and fit within their specified footprints and budgets.

MSC can help regardless if your requirement is for one machine or several machining centers. MSC prides itself in designing and manufacturing the best, highest quality and proper technology for your machining coolant specification, expected R.O.I and budget.

The Numbers Don't Lie - MSC Custom Built Coolant Reclaim System Pays for Itself in 3.2 Months!

| Coolant Recycled: 500 Gallons Per Day Manufacturing Process: North American Gun Manufacturer - Aluminum Parts Contamination Removed: Chips, Particles and Tramp Oils. | |

| |

| Customer Coolant Costs Before System Install | |

| 12-16 Drums of new coolant per month: | $17,892.00 per month |

| Monthly coolant disposal cost: | $3,360.00 per month |

| Total Monthly Coolant Costs: | $21,252.00 per month |

| Customer Coolant Costs After System Install | |

| New coolant purchases reduced to 6-8 drums per month: | $8,946.00 per month |

| Monthly coolant Disposal cost: | $1,050.00 per month |

| Total Monthly Coolant Costs: | $9,996.00 per month |

| Savings Per Month: | $11,256.00 per month |

| Savings Per Year: | $135,072.00 per year |

| Recycling System Price: | $36,250.00 |

| System Payback: | 3.22 Months |

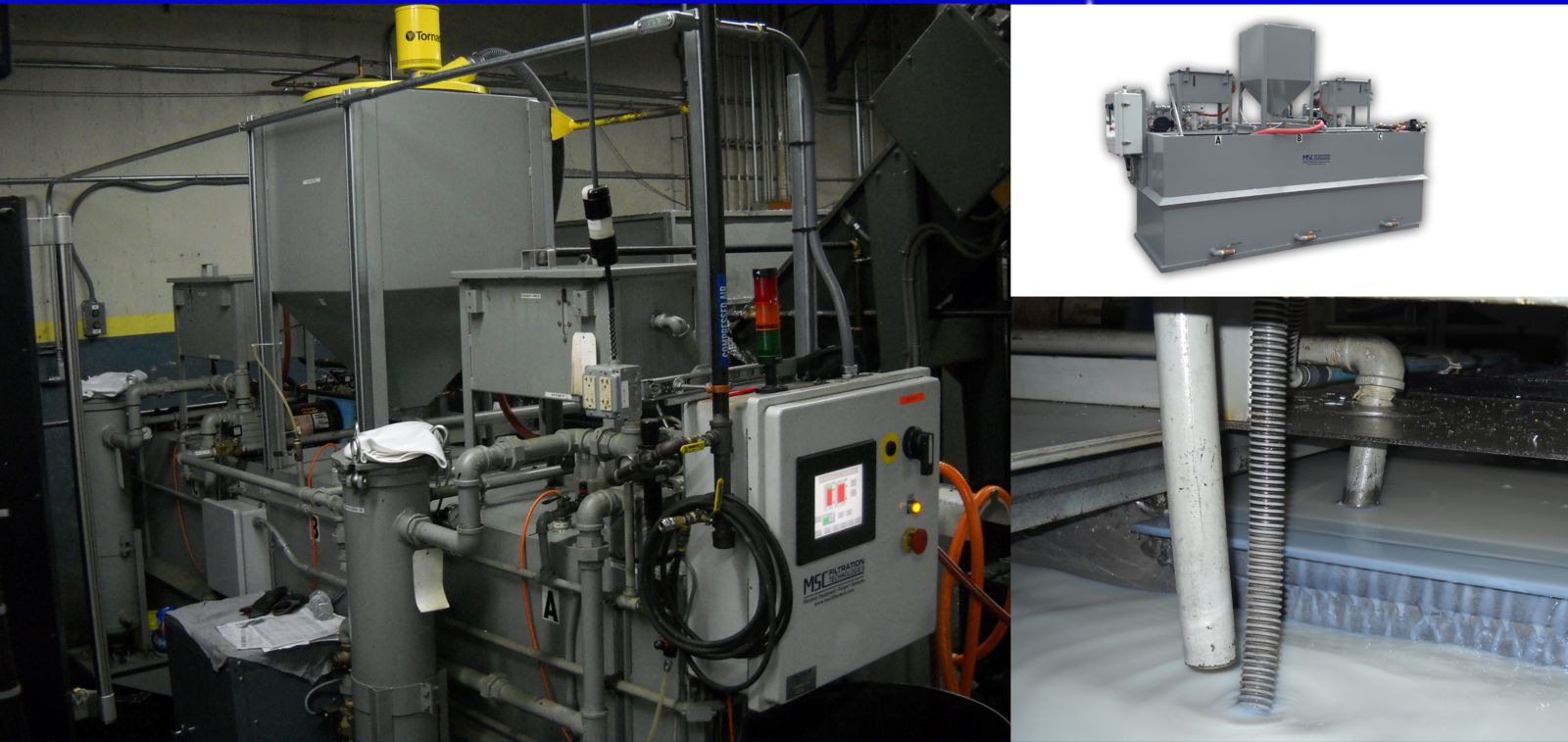

Check Out Some of Our Best Work!

Contact MSC Filtration to discuss your application or fill out and submit the coolant questionnaire and our engineering staff review it and get back to you to discuss.

Click on images for larger view.

Coolant Flow: 300 GPM

Machine Quantity: 6

Machining Process Supported: Wire Peeling - Removing the outer layer of scale created during the wire forging process and then grinding to a fine polish all on the same machine.

Equipment Integrated: Tanks, Valves Plumbing Controls, Coolant Return Pumps, 300 gpm Gravity Indexing Filter, 120,000 BTU/hr Coolant Chiller.

Coolant Flow: 400 GPM

Machine Quantity: 1

Machining Process Supported: HAAS Grinding machine aircraft engine blades and vanes - high nickel alloys and Ti.

Equipment Integrated: Tanks, Valves Plumbing Controls, Coolant Return Pumps, 400 gpm Pressure Auto Indexing Filter, coolant heat exchanger.

Coolant Flow: 250 GPM

Machine Quantity: 6

Machining Process Supported: High end swiss milling machines.

Equipment Integrated: anks, Valves Plumbing Controls, Remote Coolant Chiller, 250 gpm automatic gravity indexing filter.

Request Info