Machine Coolant Pumps

Pump Parts, Sales & Service

MSC Filtration Technologies is a distributor of several manufacturers of coolant pumps, pumps parts and services to be used with a variety of flows from 2 gpm to several hundred gpm, and a variety of pressures up to hundreds of psig. Typical applications listed below are not limited to:

- Machine Tool Cooling

- Coolant and Oil Pressure Boosting

- Lubricating

- Chip Handling

- Temperature Maintenance

- Coolant and Oil Filtration

- General Industrial

For centrifugal intank applications MSC distrbutes Brinkmann and Gusher pumps while providing its own brand of PSK pumps for self priming external tank requirements.

MSC has the expertise to help specify the correct pump for your budget, application and service.

Product Info

Brinkmann Pumps

Innovative pump solutions for every requirement

MSC FILTRATION TECHNOLOGIES is a distributor of BRINKMANN PUMPS and together we offer you a complete range of coolant pumps for every application. Our products are primarily used in different sectors within the machine tool industry. Additional applications include the printing industry, the plastic industry and the beverage industry. In any case, we focus on customer-oriented pump technology which perfectly fulfills all requirements. Let us convince you of our products' exceptional efficiency and performance!

Contact MSC for technical info.

Machine tool coolant supply Low Pressure Pumps

Wear resistant pumps for rinsing, cooling, or backflushing filters or as single stage lift pumps for chip conveyors or applications with heavy air entrainment as they occur in grinding applications.

Machine tool coolant supply Medium/High Pressure Pumps

Small and compact centrifugal or screw pumps for external cooling or for internally cooled tools with pressures of up to 200 bar. The pumps are designed to precisely meet the required duty point and can be controlled with the latest frequency converter.

Chip Handling Lifting Pumps

In these applications the focus is on lifting pumps for pump back stations, cutter pumps for cutting of stringy chips and vortex pumps. All pump types are available as vertical immersion pumps for tank mounted applications as well as horizontal end suction pumps for inline installations.

Plastic Pumps/Miniature Centrifugal

In additon to special solutions for tempering devices and industrial water applications such as glass grinding or dampening solutions recovery, this is where you will also find simple self priming suction pumps for coolant extraction from the machine bed.

Gusher Pumps

Manufacturers of Quality Pumps since 1913

MSC FILTRATION TECHNOLOGIES is a distributor of Gusher Pumps who is a manufacturer of Rumaco®, Ruthman, and Gusher® pumps. MSC, together with Gusher, represent one of the largest selection of centrifugal pumps available from a single manufacturer. Models include close-coupled pumps, end suction pumps, immersed pumps, self-priming pumps, vortex pumps, sludge pumps, multi-stage pumps, full cantilever pumps. Many in vertical or horizontal styles. These Pumps are ideally suited for small and large flow rates, and Gushers multi-stage pump is capable of heads in excess of 800 ft. Gusher and MSC also offer a range of diaphragm pumps, and turbine pumps.

Numerous models and sizes permit selection of the most hydraulically suitable pump for many capacity/head ranges without having to up or down size operating characteristics.

Gusher manufactures pumps for a wide range of applications including Din specifications, ANSI specification, machine tool and centralized coolant systems, automatic paint systems, industrial spray washers, filtration systems, phosphate and bonderizing lines just to name a few. Use the form under "Request Info" tab to contact MSC.

Industrial Machine Tool Coolant Pumps and Tank Units

Besides a wide variety of standard machine tool coolant pumps for most machining applications, MSC and Gusher offer replacement pumps for Fuji, Mitsubishi, Toshiba, Hitachi and Yasukawa.

ANSI B 73.1 Specification Horizontal End Suction Pumps

The 7071 Series is a horizontal, open impeller centrifugal pump that meets the specification of ANSI B-73.1. The series consists of 3 power end and 33 pump sizes.

Heavy Duty Vertical Pumps

For all processes and applications. The Gusher Vertical Heavy Duty Pumps provide a complete, reliable and economical solution.

7550 Series Vertical Centrifugal End Suction Pumps

The Gusher 7550 Series has been designed to give heavy duty pumping service in a wide range of industrial applications including spray booths, industrial spray washers, and coolant systems.

7600 Series Vertical Top Pull Out Centrifugal End Suction Pumps

This series of pumps has been designed to minimize maintenance. If maintenance is required, the top pull out design allows the rotating element to be removed without disturbing the mounting plate or piping.

7600 Series Horizontal Back Pull Out Centrifugal End Suction Pumps

The Gusher 7550 Series has been designed to give heavy duty pumping service in a wide range of industrial applications including spray booths, industrial spray washers, and coolant systems.

7800 Series Horizontal Centrifugal End Suction Pumps

The 7800 Series includes Gushers jet pump, self priming pumps, vertical pumps, horizontal close coupled pumps and direct drive pumps.

8000 Series Horizontal Centrifugal Self Priming Pumps

The 8000 Series is designed for a wide range of uses from agricultural to industrial, including filtration, irrigation, dewatering, transfer, industrial sump, shallow sump washers, and tank car unloading.

Vortex Model Pumps

Eight different sizes offering up to 400 feet of head and 2800 GPM capable of handling solids up to 6 inches.

Diaphragm Pumps

A wide selection of air operated diaphragm pumps for safe and cost effective transfer of all your process and waste fluids.

High Pressure Centrifugal Multistage Pumps

Gusher Multi-stage pumps offer pressures of up to 400 psi. Some models also offer dual discharges, one for low volume and high pressure, and another for low pressure high volume.

Molten Metal Pumps

Gusher Molten metal pumps handle lead, babbit, solder, tin, zinc, spelter, and other molten metals at temperatures of up to 1200 F. These pumps are standard with stainless steel shaft, pump parts made of cast iron, and carbon steel screws.

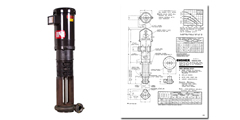

Electric Immersion Pumps

These series of pumps offers a wide breadth of applications including machine tools, chemical equipment and refigeration systems.

Vertical Turbine Pumps

These pumps are ideal for central coolant systems, cooling towers, paint, waste treatments and many more high-pressure applications.

Stainless Steel Vertical Immersion and Flanged Pumps

These series of centrifugal pumps are multifunctional products designed to convey various fluids ranging from tap water to industrial liquids at different temperatures, flow rates and pressures.

SC-CC Series Pumps

These series of pumps are for use in general industrial services.

CL-CC Series Pumps

These series of pumps are for use in general industrial services such as water purification, parts washers, paint systems and many more.

Screw Pumps

These series of pumps are used mainly for cooling lubricants and ensure performance with special case coatings

DIN Series Pumps

This series of pumps are designed to match the DIN 733 standard.

PSK SELF PRIMING 2-50 GPM PUMPS SALES & SERVICE

The MSC Filtration Technologies PSK Fluid Pump is a multi purpose, cost effective, self priming, positive displacement, progressive cavity pump that delivers long life in abrasive and non-lubricating applications. It is easy to maintain and provides the user with the option of alternating pumping flows from 2-15 gpm with just the simple switch of a rotor and stator.

The PSK progressive cavity design forms a series of cavities which contain the pumped fluid. As the rotor turns, the cavities "progress" from the suction to the discharge side of the pump moving the fluid.

This results in a constant, uniform, non pulsating flow that provides low shearing and reduced degredation of pumped materials. The PSK Pump also provides low velocity capability for pumping of viscous fluids.

In abrasive applications, the stators ability to deform slightly to accomodate solids particles contributes to its abrasive resistance and the pumps ability to handle abrasive solids.

PSK Pump Lasts 32 Years in the Field

Request Info

.jpg)