How Pratt & Whitney's North Berwick Aero Systems Saves 400,000 Gallons of Water Each Year with FilClean CMS

How Pratt & Whitney's North Berwick Aero Systems Saves 400,000 Gallons of Water Each Year with FilClean CMS

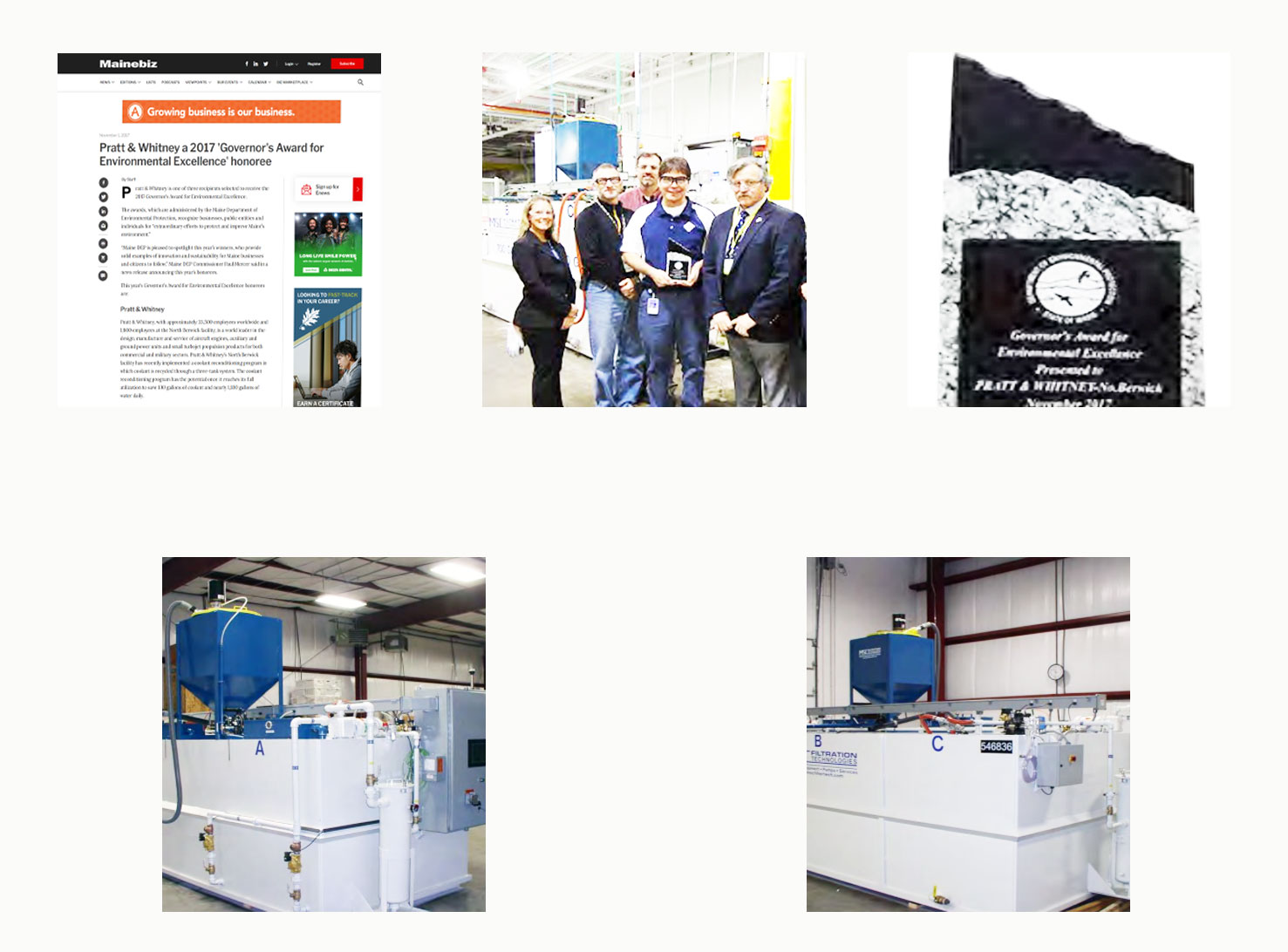

Imagine 147 inches of snow – more than 12 feet – piled on one acre of ground. When the snow melts, that’s how much water Pratt & Whitney’s North Berwick facility saves every year through its coolant reconditioning program. Pratt & Whitney’s North Berwick facility implemented a MSC coolant reconditioning system to recycle coolant through a three-tank system.

The program captures and reconditions coolant so it can be used again rather than disposed. It can save 100 gallons of coolant per day, and reduce daily water use by 1,100 gallons, saving $52,000 per year on coolant concentrate costs and reducing water use by nearly 400,000 gallons annually.

The program recently won recognition from Maine Gov. Paul R. LePage and the Maine Department of Environmental Protection as a recipient of the 2017 Governor’s Award for Environmental Excellence. The award recognizes businesses, public entities and individuals who go above and beyond simply complying with environmental regulations.

“I am so proud of the exceptional leadership from our EH&S and Site Services teams,” said Patrick Regan, general manager of North Berwick Parts Center. “It’s truly a great feeling to know that our employees’ passion and leadership not only create the most advanced engines in the world but their stewardship and protection of the natural environment are simply unmatched!” “The coolant reconditioning system is more than a great accomplishment in reducing our environmental footprint,” said Mike Newsky, associate director, North Berwick Parts Center. “This is an example of how meeting our environmental goals helps us to achieve our business objectives by increasing efficiency and driving profitability.”

By reducing water use and the amount of coolant that must be disposed, the coolant reconditioning project at North Berwick helps support the Pratt & Whitney and United Technologies 2020 Sustainability Goals, which set targets for core metrics including energy savings, greenhouse gas reduction and water conservation. Pratt & Whitney has invested almost $60 billion in more than 800 environmental projects since 2006. The North Berwick facility includes Environment, Health & Safety improvement initiatives as part of the annual planning process.

“Our proactive strategy of incorporating reclaimed coolants into the metal working fluid

management process demonstrates a continued commitment to environmental stewardship and

conservation of natural resources,” said Tom LeBlond, associate director of EH&S at North

Berwick.

Download The Success Story