PHoenix™ Membrane Oil Dehydrator and Purifier Handles Gear Box Water Ingression

Water Ingression - Paper Plant Gear Box

A paper plant was having steady water ingression into its caustisizer gear box. This ingression was caused by hose down water needed to clean lime off of the gear box and associated components finding its way into the oil reservoir through gasket leaks

The Solution: PHoenix™ C1 1 gpm purifier cart

A PHoenix™ 1 gpm cart was installed on the 300-gallon oil reservoir with 220 weight synthetic oil.

The Results:

After the first oil sample was pulled it was found water levels were as high as 3000 ppm and iso cleanliness counts were 21/20/19. After the PHoenix ™ completed the task after one-month water level had dropped to below 300 ppm and iso counts to 17/15/13.

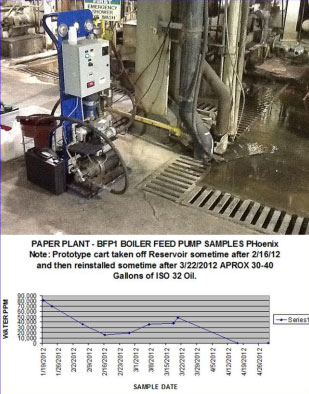

Water Ingression - Paper Plant Boiler Feed Pump Reservoir

A paper plant was having constant water ingression into its 50-gallon boiler feed pump reservoirs. The oil was significantly emulsified and so the only way for the customer to keep up with the leak was to drain 5 gallons of oil from the bottom of the reservoir and add new oil weekly.

The Solution: PHoenix™ C1 1 gpm purifier cart

The PHoenix ™ was ran for one month and found that water reduced from 8% down to approximately 1%. After that time, the unit was removed from the reservoir and water content increased back from 1% up to 5% where the PHoenix ™ was reinstalled.

The Results:

After one more month of running the PHoenix™ water had dropped to less than 300 ppm. This happened without having to perform any maintenance on the unit at all.

Learn More About The PHoenix Solution | Download the Impact Story