Coolant Oil Chillers

High Quality American Made

MSC Filtration Technologies represents Turmoil Chillers - an American company who manufactures high quality, heavy duty oil and water chillers out of its plant in West Swanzey, NH USA.

MSC and Turmoil offer a complete line of oil and coolant chillers for many applications not limited to Machine Tool Coolants and Oils, Medical Equipment, Linear Motors, Hydrostatic Bearings, Lasers, X Ray Equipment , EDM, High Speed Spindles and Hydraulics.

Turmoil Coolers provide the precise temperature control of recirculating coolants that is necessary for precision machining and reliable equipment operation.

Click on the applications and engineering tabs to learn more about sizing the correct cooler for your application and/or Contact MSC today to speak to one of our engineers who will be glad to guide you through the process or answer any technical questions.

Applications & Engineering Info

Models Available

Click on image for larger view.

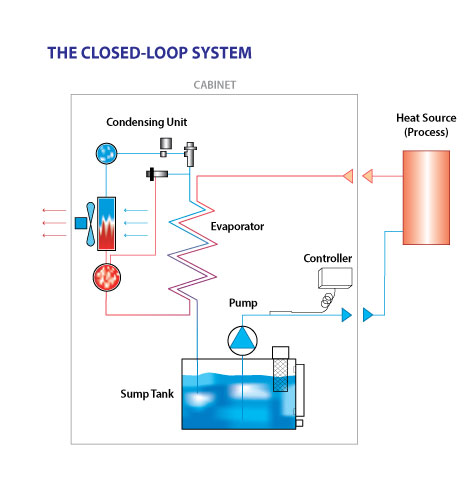

R- Closed Loop Chillers

Self-Contained Recirculating Chillers

Closed-Loop chillers recirculate coolant from a tank mounted on board the chiller, through a sealed coolant loop and heat source (process) and back to the tank. The tank, pump, and evaporator are all on board the chiller.

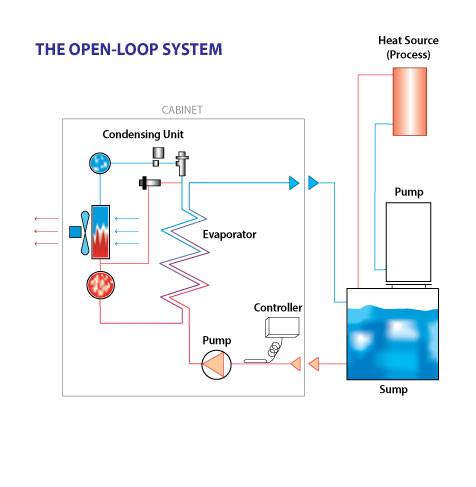

RO- Open Loop Chillers

Recirculate Fluid from a Remote Tank

Open-Loop chillers recirculate fluid from a remote tank, through the chiller and back to the tank. The chiller works to maintain a constant fluid temperature in the tank. The pump and evaporator are on board the chiller. The tank is remote.

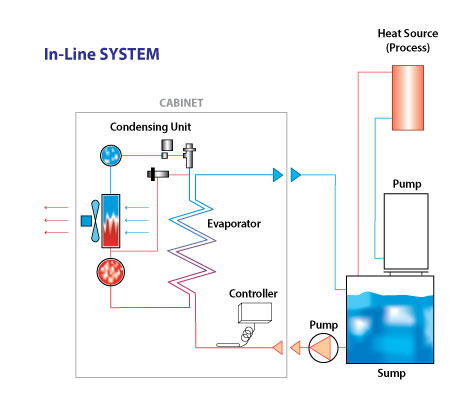

IL- In-Line Chillers

Installed "In-Line" Where the Process Already Contains a Pump

In-Line chillers cool fluid that is passing through under pressure. Only the evaporator is in the chillers. Both the pump and tank are remote.

These chillers are often used in applications where it is advantageous to have the pump mounted on or near the tank to recirculate fluid through the chiller and back to the tank.

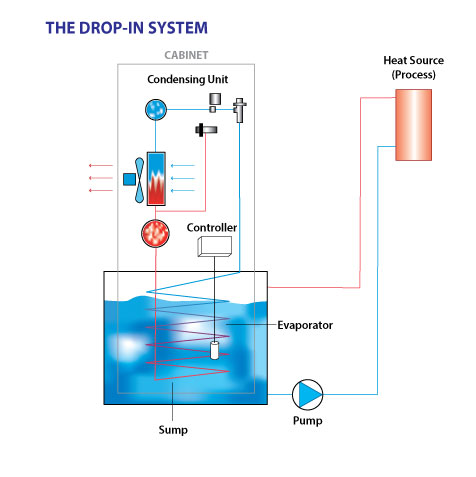

DI- Drop-In Chillers

Space-Saving Design to Cool Fluids in a Tank

Drop-In coolers are designed to be mounted on top of a tank to cool the fluid that is surrounding the coils. The stainless steel immersion coil type evaporator is submerged into the fluid in the tank. A small agitation pump continuously moves the fluid around the evaporator coils ensuring proper heat transfer. The temperature controller senses the fluid temperature and controls the chillers cycling to maintain the fluid in the tank at the set-point.

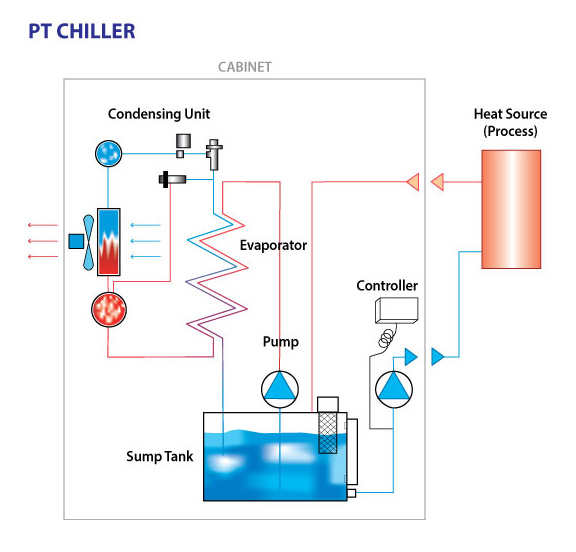

PT- Process Tank Chillers

Two Loop Chiller for True Process Applications

The PT Model Chiller Uses Two pumps with one process tank. One pump circulates coolant through the evaporator to maintain a constant tank temperature, while a second pump circulates coolant from the process tank (on-board chiller) through the process and then back to the process tank.

Chiller Sizing

Turmoil application engineers are specialists, available to help you select or design a cooling system to meet your specific needs. They are very familiar with your applications and our equipment. Turmoil prides itself on being able to provide accurate technical data when you need it. So, if you need help, give Turmoil a call.

DETERMINING THE HEAT LOAD

The heat load is the amount of heat to be removed from the coolant as it passes through the chiller. In order to size a cooler, this heat load must be accurately determined. This can be done in several ways:

- Measure flow and temperature change.

The most accurate way to determine heat load is to measure the flow of the coolant. (This can be done by timing how long it takes to fill a five-gallon bucket.) Measure the change in temperature (Δ T) of the coolant as it enters and leaves the heat source. Calculate the heat load as follows:

Flow Rate (gal/hr) x Coolant Weight (lbs/gal) x Specific Heat of Coolant x ΔT°F = BTU/HR

- Measure the change in temperature of the coolant in the sump.

If there is a sump on your machine tool, measure the temperature of the coolant in the sump before machine startup. Then measure the temperature of that same coolant at 30-minute intervals for three hours after start-up while the machine is operating at full capacity. Determine the total volume of coolant in the sump and coolant loop. Take the hour interval with the greatest temperature change and plug the numbers into the following formula:

Gallons of Coolant x Coolant Weight (lbs/gal) x Specific Heat of Coolant x ΔT°F = BTU/HR - Size the cooler by the motor horsepower.

The coolant is heated either directly or indirectly by a motor or motors. Theoretically, if you know the motor horsepower you can easily determine the heat load. But, it is not always so simple. Duty cycle, motor efficiency, and ambient heat loss or gain can have a great effect on the heat load. However, if the motor horsepower is known and its operation is fairly steady at maximum output:

1HP = 746 WATTS = 2545 BT/HR

DETERMINING APPLICATION & COOLANT

It is very important to determine the type of cooler that is required. All applications involve a fluid passing through an evaporator (heat exchanger), but how does the coolant get there?

Closed-Loop coolers recirculate coolant from a tank mounted in the cooler, through the heat load and back to the tank. The tank, pump, and evaporator are all in the cooler.

Open-Loop coolers recirculate coolant from a remote tank, through the cooler and back to the tank. The pump and evaporator are in the cabinet. The tank is remote.

In-Line coolers cool fluid that is passing through the cooler under pressure. Only the evaporator is in the cooler. The pump and tank are remote.

Drop-In coolers are mounted on top of the coolant tank with the stainless steel evaporator coils submerged in the coolant.

Because water and oil have such different heat transfer characteristics, it is very important that the type of coolant being used is determined. If in doubt, specify an OCO cooler.

Water-Based Coolants are fluids that contain not more than 5% oil. These coolants may contain additives such as rust inhibitors, algaecides, and/or up to 30% glycol.

Oil-Based Coolants are fluids that contain more than 5% oil. Soluble oils, semi-synthetic fluids, hydraulic oils, cutting oils, and spindle oils are typical.

Clean Coolants are fluids that do not contain particles that could clog the pump or evaporator. The coolant is usually sealed from contamination or filtered to remove damaging particles.

Dirty Coolants contain or potentially can contain particles such as fines or chips that could clog the pump or evaporator. An In-Line filter or cleanable evaporator is often required.

Applications

Closed-Loop Chillers

- High-Speed Spindles

- Lasers

- Power Supplies

- Diffusion Pumps

- Jacketed Vessels

- Chill Rolls

- Injection Molding

- Linear Motors

- Medical Equipment

- Welding

- Vacuum Systems

- Heat Exchangers

Open-Loop Chillers

- Coolant Sumps

- Filtration Tanks

- Hydraulic Tanks

- EDM

- Fish Tanks

- Process Tanks

- Quench Tanks

- Headstocks

- Gear Boxes

In-Line Chillers

- Coolant Systems

- Filtration Systems

- Hydraulic Systems

- EDM

- Cold Spray

- Batch Cooling

- Film Developing

- Ingredient Water

- Food Processing

Drop-In Chillers

- Coolant Tanks

- Filtration Tanks

- EDM

- Settling Tanks

- Quench Tanks

- Fish Tanks

Request Info