FilClean™CMS

Centralized Machine Tool Coolant Management System and Recycler

The FilClean™ CMS Machine Tool Coolant Management System

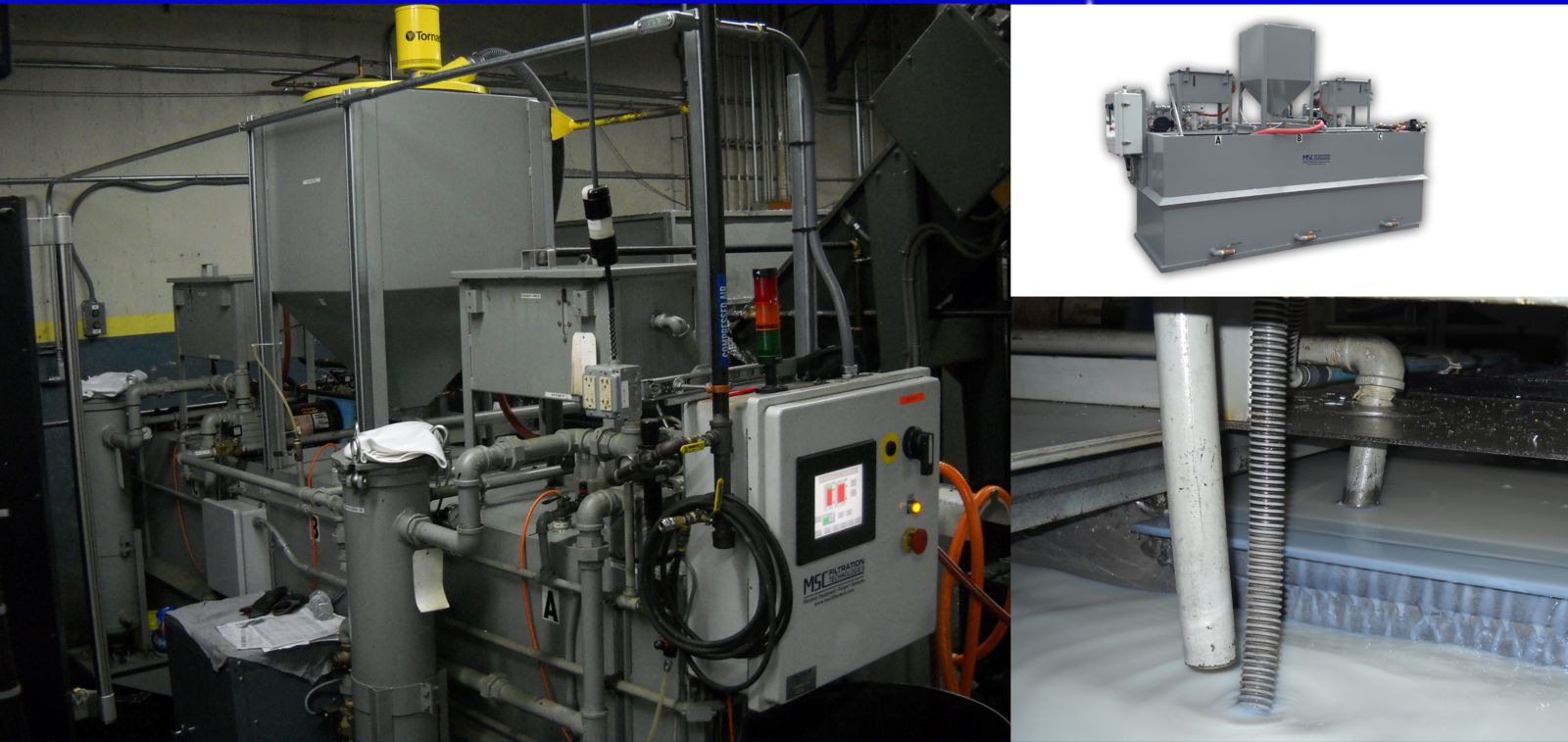

The FilClean™ CMS Machine Tool Coolant Management System is a cost-effective solution that empowers customers to recycle their coolant, resulting in significant savings on new machine tool coolant costs annually. Its advanced design provides a centralized location for removing tramp oil and particulates from coolant, along with coolant rebalancing and optional ozone treatment to control biological growth.

The FilClean™ CMS Machine Tool Coolant Management System Offers:

- Reduce Annual Coolant Purchase

- Improve Tool Life

- Reduce Dermatological Issues

- Reduce Machining Scrap

- Improve Parts Finishes

User Friendly and Automatic Operation

The FilClean CMS is incredibly user-friendly, requiring very little operator attention or training to operate. Once coolant has been pumped in, the processing is fully automatic, making it an ideal solution for businesses looking to streamline their coolant management process. Moreover, it's gentle on coolant and does not affect its chemistry, which ensures longevity and sustainability.Minimal Maintenance

One of the standout features of the FilClean CMS is its simplicity. With only two moving parts, two air diaphragm pumps,it requires minimal maintenance, and its running costs are exceptionally low. The only consumables required are disposable bag filters, which cost just a few dollars each, or roll media, which costs a few dollars a yard if the optional FilClean IDX gravity indexing inlet filter is chosen.Customizable

Finally, the FilClean CMS is upgradeable, providing customers with a range of options to customize their coolant management system. These include a variety of inlet filter options, magnetic cleanable filters, and ozone treatment. This flexibility ensures that the FilClean CMS can meet the evolving needs of businesses as they grow and develop.How Pratt & Whitney's North Berwick Aero Systems Saves 400,000 Gallons of Water Each Year with FilClean CMS

Imagine 147 inches of snow – more than 12 feet – piled on one acre of ground. When the snow melts, that’s how much water Pratt & Whitney’s North Berwick facility saves every year through its coolant reconditioning program. Pratt & Whitney’s North Berwick facility implemented a MSC coolant reconditioning system to recycle recycled through a three-tank system.

The program captures and reconditions coolant so it can be used again rather than disposed. It an save 100 gallons of coolant per day, and reduce daily water use by 1,100 gallons, saving $52,000 per year on coolant concentrate costs and reducing water use by nearly 400,000 gallons annually.

Product Specs & Ordering Info

Download Literature

Download Literature

The Numbers Don't Lie - MSC Custom Built Coolant Reclaim System Pays for Itself in 3.2 Months!

| Coolant Recycled: 500 Gallons Per Day Manufacturing Process: North American Gun Manufacturer - Aluminum Parts Contamination Removed: Chips, Particles and Tramp Oils. | |

| |

| Customer Coolant Costs Before System Install | |

| 12-16 Drums of new coolant per month: | $17,892.00 per month |

| Monthly coolant disposal cost: | $3,360.00 per month |

| Total Monthly Coolant Costs: | $21,252.00 per month |

| Customer Coolant Costs After System Install | |

| New coolant purchases reduced to 6-8 drums per month: | $8,946.00 per month |

| Monthly coolant Disposal cost: | $1,050.00 per month |

| Total Monthly Coolant Costs: | $9,996.00 per month |

| Savings Per Month: | $11,256.00 per month |

| Savings Per Year: | $135,072.00 per year |

| Recycling System Price: | $36,250.00 |

| System Payback: | 3.22 Months |

FilClean™ CMS Features

- Minimal operator involvement

- Minimal consumables, low cost of ownership

- Few moving parts

- Removes tramp oils

- Fine particulate removal

- Provides a storage location for used coolants during machine downtime

- Reduces water use

- Provides consistent coolant quality among all machining units

- Can handle heavy and varying contamination loads and ingression